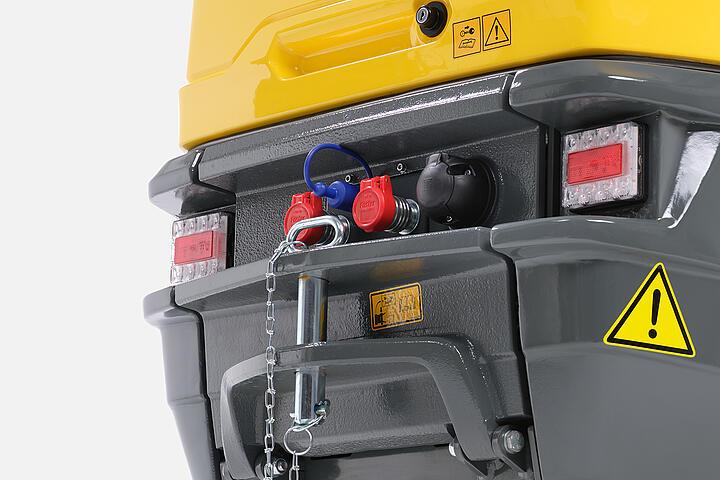

The WL300e expands the zero emission portfolio of compact electric wheel loaders from Wacker Neuson. The built-in 48-volt lithium-ion battery is available in three power levels, so that running and charging times can be optimally adapted to the work requirements. The WL300e works on site completely exhaust-free and with significantly lower noise emissions. For the user, this means greater flexibility in use, environmental protection and significant savings in operating costs. The optionally available low front carriage in combination with a short loading arm ensure an excellent overview and a significantly increased tipping load.